Table of contents

- Understanding Biodegradable Bags: Science and Environmental Logic

- Why Choose a Professional Biodegradable Bag Manufacturer

- Customization Services: Creating Exclusive Eco Packaging for Every Brand

- From Raw Materials to Market: How Guanzhong Ensures Quality and Compliance

- Collaborating with Guanzhong: Your Partner for Custom Eco Packaging

Understanding Biodegradable Bags: Science and Environmental Logic

In the context of the global “plastic reduction” and “carbon neutrality” trend, biodegradable bags have become an ideal alternative to traditional plastic packaging. Conventional PE plastic bags take hundreds of years to decompose under natural conditions, whereas biodegradable bags can naturally break down in compost or soil without generating microplastic pollution. This is why governments, enterprises, and consumers alike are increasingly focusing on green packaging solutions.

Definition and Types of Biodegradable Bags

A biodegradable bag is a type of packaging that can be decomposed into carbon dioxide, water, and biomass through microbial action under natural environments or industrial composting conditions. Common types include:

- PLA (Polylactic Acid): Derived from lactic acid fermented from corn starch or sugarcane

- PBAT (Polybutylene Adipate Terephthalate): Offers good toughness and flexibility

- PHA (Polyhydroxyalkanoates): Capable of biodegradation in natural and marine environments

- PLA+PBAT Composite Materials: Combines the environmental benefits of PLA with the flexibility of PBAT.

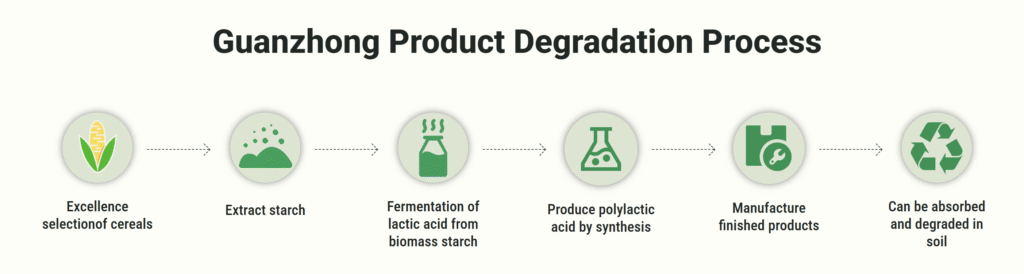

Role of Corn Starch Materials

Guanzhong uses corn starch-based biopolymers as the main raw material. The process includes fermentation to produce lactic acid, followed by polymerization into PLA. This renewable material is non-toxic, odorless, and can naturally degrade under composting conditions, truly achieving “taken from nature, returned to nature.”

Scientific Breakdown of the Degradation Process

Under industrial composting conditions (approximately 58°C, humidity ≥50%), PLA materials can fully decompose into water and carbon dioxide in about 180 days without polluting soil or groundwater. This process has been verified by international standards such as ASTM D6400, EN13432, and DIN EN 13432.

Why Choose a Professional Biodegradable Bag Manufacturer

Manufacturing biodegradable bags is not just a simple replacement of plastic; it involves material science, degradation mechanisms, and production technology. Choosing a professional biodegradable bag manufacturer or bio bag manufacturer ensures that products achieve the optimal balance between environmental performance and functionality.

Guanzhong’s Strengths and Scale

Guanzhong is located in Dongping Light Industry Avenue, Yongchun County, Quanzhou, Fujian Province, and is one of China’s leading companies in biodegradable materials and eco-friendly packaging.

- Factory area: 100,000㎡

- Annual production capacity: 90,000 tons

- Staff: 180 professional employees

- Mold development time: 7 days

- Production time: 15 days

- Service type: OEM/ODM customization

The company has independent production lines for pelletizing, thermoforming, injection molding, and film blowing, along with a dedicated R&D building and laboratory, enabling rapid response to diverse customer customization needs.

International Standards and Full-Process Quality Control

Guanzhong strictly follows the ISO9001 management system. Every batch of product undergoes traceable, digitalized control from raw material inspection to final shipment.

All products pass food contact safety tests, ensuring suitability for food, medical, and consumer applications, truly achieving dual assurance of safety and environmental protection.

Customization Services: Creating Exclusive Eco Packaging for Every Brand

Eco-friendly packaging should not just be a “green substitute”; it should reflect the brand’s image and values. Guanzhong provides one-stop customization services, helping clients achieve packaging differentiation and sustainable development goals.

Scope of Customization

Guanzhong supports the following customization options:

- Logo customization: Brand logos, slogans, or patterns

- Color design: Transparent, natural colors, or exclusive color schemes

- Size and thickness: Precisely customized according to product requirements

- Patterns and surface finishes: Printing or embossing effects

- Material combinations: PLA, PBAT, and biobased composite films

Minimum order quantity (MOQ) is 1 ton of raw materials, flexibly meeting diverse customer needs.

Customization Process

- Communication and requirements confirmation: Customers provide design ideas and specifications

- Sample design and approval: Completed and shipped within 7 days

- Raw material selection and testing: Determining material ratio and performance parameters;

- Mass production: Completed within 15 days

- Packaging and final inspection: Ensuring consistent appearance and performance.

From Raw Materials to Market: How Guanzhong Ensures Quality and Compliance

Guanzhong’s advantage lies not only in equipment and production capacity but also in full-chain management of quality, environmental performance, and compliance.

Raw Material Sourcing and Traceability

All biobased materials come from renewable plants (corn, cassava, etc.) and are fermented into lactic acid, then polymerized into PLA. The company strictly controls the supply chain to ensure stable, traceable, and environmentally friendly raw materials.

Production Process and Technology

The production process includes:

Raw material inspection → Film blowing → Printing → Cutting → Packaging → Final inspection

All procedures are conducted in temperature-controlled cleanrooms, ensuring smooth surfaces, uniform thickness, and zero contamination.

Production Line Configuration

- Injection molding lines: 50 lines, ~2000 tons/month

- Vacuum forming lines: 8 lines, ~800 tons/month

- Film blowing + bag making lines: 75 lines, ~1500 tons/month

- Biobased modified material lines: 8 lines, ~2000 tons/month

- Straw extrusion lines: 5 lines, ~250 tons/month.

Testing and Certification System

Guanzhong is equipped with advanced testing instruments, including:

- TGA Thermogravimetric Analyzer (thermal stability)

- FTIR Spectrometer (molecular structure analysis)

- Biodegradation performance testers (composting decomposition verification)

All products meet ASTM, DIN, GB/T, FDA, SGS, BPI standards, complying with global environmental regulations and food contact safety requirements.

Collaborating with Guanzhong: Your Partner for Custom Eco Packaging

Working with Guanzhong is not just purchasing products—it’s joining a global sustainable packaging ecosystem.

Collaboration Models

- OEM customization: Developing exclusive packaging per brand requirements

- ODM solutions: Providing mature molds and structural designs

- Long-term supply agreements: Ensuring stock and delivery schedules

- Joint brand promotion: Building a shared eco-friendly brand image

Reasons to Choose Guanzhong

- Strong expertise as a biodegradable bag manufacturer and bio bag manufacturer: Advanced R&D and full process control

- Technology leadership: 10 patents and an in-house R&D center

- Full certifications: ISO, FDA, DIN, BPI, SGS coverage

- Rapid response: 7-day mold development, 15-day mass production

- International collaboration: Products exported to Europe, America, Japan, Korea, and Southeast Asia

Customer Support System

Guanzhong provides full-process services from design, sampling, production, to logistics, with a professional after-sales team offering real-time technical and order support worldwide

Collaboration Process

Consultation → Design confirmation → Sampling → Contract signing → Mass production → After-sales tracking

Each stage is managed by dedicated personnel to ensure smooth communication and efficient project implementation.

| Start Your Customization | WhatsApp: +86 13665956245 | Email: peters@quanzhong-bio.com |

Biodegradable materials are redefining the future of the packaging industry. With stricter environmental regulations and growing consumer awareness, green packaging is no longer a choice but a necessary step for businesses.

Guanzhong focuses on science, quality, and innovation, specializing in the research, development, and application of biobased and biodegradable materials. With professional technical expertise, strict quality management systems, and comprehensive OEM/ODM customization services, Guanzhong is an important driver in the global sustainable packaging movement.