Table of contents

- Why Choose Guanzhong as Your Biodegradable Plate Manufacturer

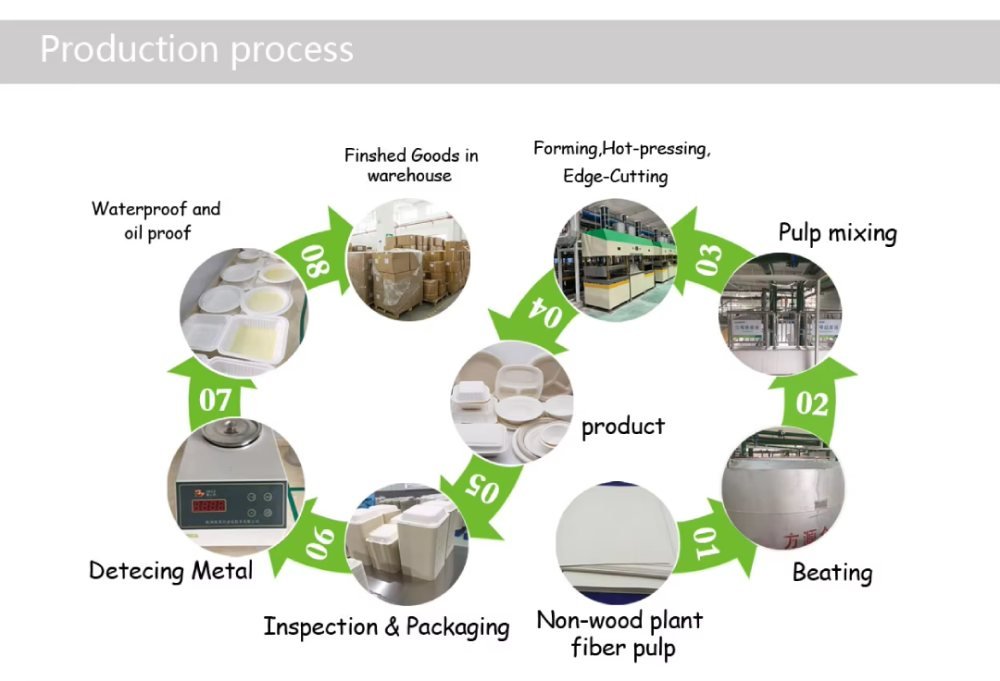

- From Raw Materials to Finished Products: Biodegradable Tableware Production Process

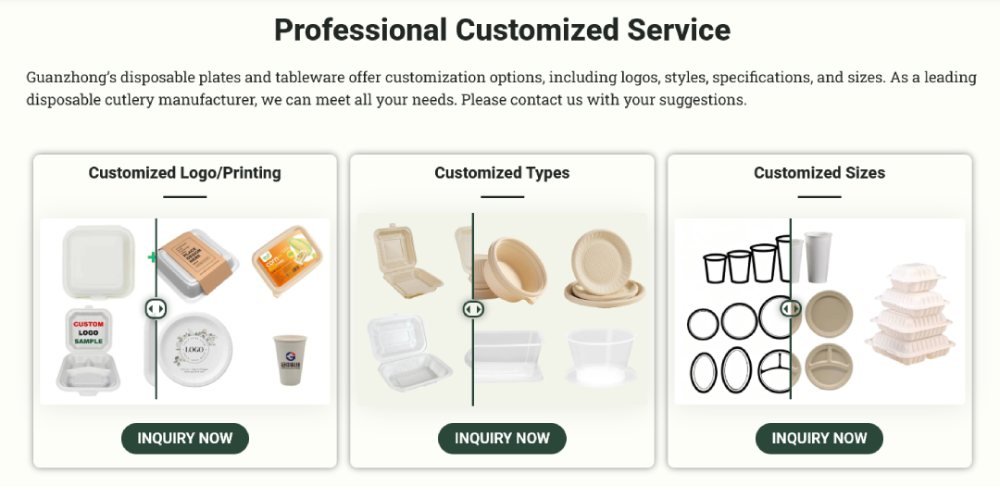

- Custom Services: Creating Brand-Exclusive Eco Tableware

- Cooperation with Guanzhong: From Requirements to Delivery

- Common Issues in Biodegradable Tableware Production and Solutions

Why Choose Guanzhong as Your Biodegradable Plate Manufacturer

- Company Overview: Guanzhong specializes in the research and production of corn-starch-based biodegradable disposable tableware, covering plates, bowls, forks, spoons, straws, and takeaway boxes. Using bio-based and biodegradable composite materials, the products balance strength and environmental performance.

- Factory Strength: The industrial park spans nearly 200,000 m², with standardized workshops exceeding 100,000 m². Guanzhong operates 50 injection molding lines, 8 thermoforming lines, 50 film-blowing and printing lines, 25 bag-making lines, 3 sheet extrusion lines, 5 masterbatch production lines, and 5 straw extrusion lines. With an annual output of 90,000 tons and 180 skilled production staff, the factory ensures flexible production and large-scale supply.

- Quality Assurance: Strictly following the ISO9001 quality system, Guanzhong products comply with GB/T 20197, GB/T 19277.1, GB/T 4806.7, ASTM D6866, ASTM D6400, DIN EN 13432, and FDA food contact testing. Multiple international industrial compost certifications and BPI certifications have also been obtained.

- Customization Capability: Supports small to large batch customization, allowing adjustments to thickness, size, color, and logo. Minimum order quantity: 30,000 pieces for plates and tableware, 300,000 pieces for forks and knives. Mold production time: 7–45 days; manufacturing time: 7–15 days. Rapid response to market demand is guaranteed.

- Sustainable Development Concept: Products are 100% compostable. Green manufacturing processes and energy-efficient equipment are used throughout production, strictly controlling carbon emissions and replacing conventional plastics with bio-materials to achieve a full lifecycle of environmental protection.

From Raw Materials to Finished Products: Biodegradable Tableware Production Process

- Raw Material Selection: Uses corn starch, bio-based PLA, and PBAT materials, ensuring renewability and biodegradability, with bio-modification for improved processing performance.

- Formulation and Modification: Through toughening, plasticizing, and esterification modification, materials achieve improved flexibility, heat resistance, and tensile strength while maintaining high degradation rates.

- Injection Molding and Forming: Granulated materials are processed through injection molding, thermoforming, and film-blowing equipment. Intelligent mold temperature control ensures dimensional accuracy, surface smoothness, and structural strength.

- Customization Features: Color, logo, and pattern designs can be incorporated. 3D modeling and sample creation ensure optimal product presentation before mass production.

- Quality Inspection: Anti-pressure, heat resistance, oil resistance, and degradation tests ensure stable performance for takeout, catering, and frozen applications.

- Packaging and Shipment: Environmentally friendly packaging is used. Options include individual packaging, set packaging, or custom brand packaging, combined with standardized logistics to ensure safe delivery.

Custom Services: Creating Brand-Exclusive Eco Tableware

Eco-friendly tableware is not only a green alternative but also an extension of brand image and values. Guanzhong provides one-stop customization services, helping clients differentiate their tableware while promoting sustainable development.

Customization Options

Guanzhong offers multiple customizable options:

- Logo Customization: Brand logos, slogans, or unique designs can be applied on plates, bowls, forks, spoons, straws, and takeaway boxes.

- Color Design: Natural, transparent, or brand-specific colors are available to maintain visual consistency.

- Size and Thickness: Accurate adjustments to meet functional and usage requirements.

- Patterns and Surface Treatments: Printing, embossing, or relief effects enhance product aesthetics.

- Material Combinations: PLA, PBAT, and bio-based composites can be optimized for heat resistance, flexibility, and degradation requirements.

These options allow clients to create exclusive brand eco-tableware, making the products an extension of their brand image while meeting environmental and market demands.

Cooperation with Guanzhong: From Requirements to Delivery

Step 1: Requirement Communication and Plan Confirmation

Clients provide intended use, size, quantity, and budget information. Guanzhong offers professional advice and proposes a collaboration plan.

Step 2: Design and Sample Phase

3D modeling and sample production are conducted, with a sample cycle of approximately 7 days. After approval, small-scale trial production begins.

Step 3: Mass Production and Process Quality Control

Automated equipment ensures consistency, with strict inspections for dimensions, heat resistance, strength, and degradation performance.

Step 4: Packaging, Logistics, and International Delivery

Various packaging options are offered, complying with international shipping standards for safe and timely delivery.

Step 5: After-Sales Service and Continuous Cooperation

Regular follow-ups, product maintenance, and reorder support are provided, along with guidance for new product development and improvement.

Common Issues in Biodegradable Tableware Production and Solutions

Molding Defects, Deformation, and Fragility

Often caused by uneven raw material blending or incorrect mold temperature. Optimizing formulations and precise mold temperature control improves molding rate and damage resistance.

Material Ratios and Additive Optimization

Adjusting PLA, PBAT, and starch composite ratios and adding toughening agents, plasticizers, and stabilizers ensures heat resistance, flexibility, and biodegradability.

Storage and Transportation Tips

Store in dry, ventilated environments, avoiding high temperature, heavy pressure, and moisture. Protective packaging reduces deformation or breakage during transport.

Testing Standards and Technology Upgrades

Reference ASTM D6400, EN13432, and GB/T 20197 standards. Continuous upgrades to pressure, heat, and degradation simulation testing equipment ensure product reliability.

| Start Your Customization | WhatsApp: +86 13665956245 | Email: peters@quanzhong-bio.com |

Custom eco-friendly tableware is a key way for enterprises to demonstrate environmental responsibility and enhance brand value. Guanzhong leverages advanced production capacity, extensive customization experience, and rigorous quality management to help clients achieve sustainable development and high-quality outcomes. As a trusted disposable cutlery manufacturer and biodegradable plate manufacturer, Guanzhong provides long-term professional services for global clients, helping brands stand out in the eco-friendly trend and making tableware a powerful extension of brand identity, achieving both market value and social responsibility.