Table of contents

Over the past few decades, plastic has permeated nearly every aspect of our lives—from supermarket shopping bags to express delivery packaging to takeout containers. Its convenience is irresistible. However, this “convenience” also carries a heavy environmental burden. According to the United Nations Environment Programme, over 300 million tons of plastic waste are generated globally each year, much of which cannot be effectively recycled and ends up in oceans or landfills, causing serious ecological pollution.

Against this backdrop, the emergence of biodegradable bags offers a more sustainable solution. Unlike traditional plastic bags, biodegradable bags can be naturally broken down by microorganisms into carbon dioxide, water, and organic matter. They do not remain in the environment for long periods, reducing the burden of “white pollution.”

As a major global manufacturing hub, China plays a key role in this sector. Guanzhong is a leading provider of this technology. As China’s top custom bio bag manufacturer, Guanzhong not only focuses on the research and development of environmentally friendly materials but also continuously innovates in production, design, and global supply chain management. For businesses seeking a high-quality, customizable, and reliable eco-friendly packaging partner, Guanzhong is undoubtedly a trustworthy choice.

Materials and Environmental Advantages of Degradable Bags

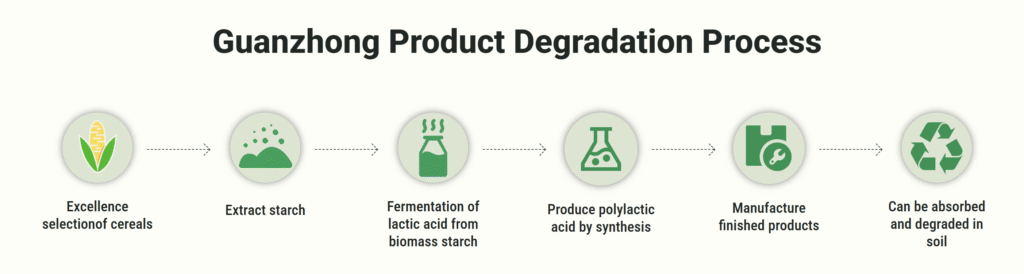

To understand the true value of degradable bags, we first need to understand their core material. Unlike traditional polyethylene (PE) plastic, degradable bags are typically made from bio-based or biodegradable materials such as PLA (polylactic acid), PBAT (polybutylene adipate/terephthalate), and PCL (polycaprolactone).

PLA is a biomaterial derived from plant starch (such as corn, cassava, or sugarcane). It is produced by fermenting sugar to produce lactic acid, which is then polymerized into polylactic acid. Its advantages lie in its renewable, non-toxic, and compostable nature. PBAT, a more flexible degradable material, offsets the brittleness of PLA, making the resulting bags more durable and sturdy. Guanzhong often uses a composite formula of PLA and PBAT in its production, ensuring bags that combine excellent environmental performance with the strength required for daily use.

During the decomposition process, these materials naturally decompose into carbon dioxide and water under appropriate humidity, temperature, and microbial conditions, leaving no microplastic residue and preventing secondary pollution in the soil or ocean. In contrast, traditional plastic bags can take hundreds of years to degrade.

In addition to their environmental performance, degradable bags have also significantly improved their practicality. Guanzhong’s products utilize a specialized film blowing and lamination process to ensure they possess excellent stretchability, water resistance, temperature resistance, and printability. Whether used for food packaging, shopping bags, or courier bags, they can completely replace traditional plastic bags in terms of functionality.

Precisely because of their combined environmental and practicality, degradable bags have become a key choice for major brands in their transition to green packaging.

Guanzhong Customized Degradable Bag Services

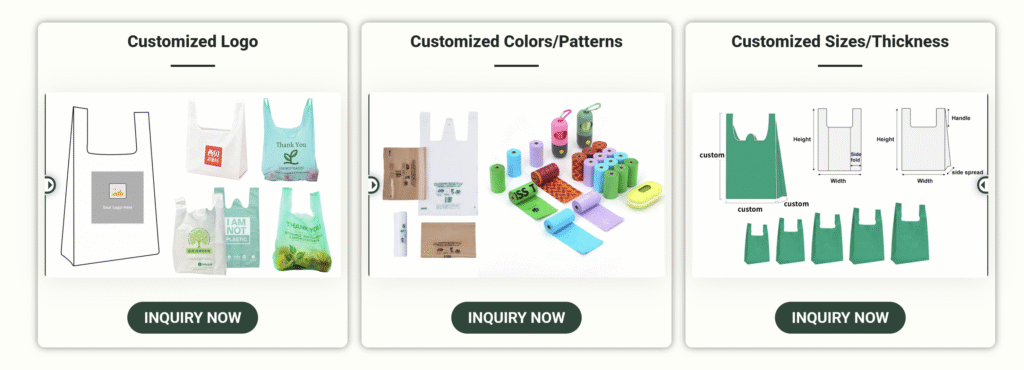

Many companies choose Guanzhong not only for its environmentally friendly products but also for its highly flexible customization capabilities. In the eco-friendly packaging market, customization has become a crucial means of brand differentiation. Guanzhong understands this and offers one-stop OEM/ODM services, from design to mass production.

Logo and pattern customization. Whether it’s a simple logo or complex multi-color print, Guanzhong can perfectly convey your brand image on the bag through high-definition flexographic printing or solvent-free lamination technology. The printing inks are all environmentally friendly, water-based and solvent-free, ensuring the bags release no toxic substances during degradation.

Customizable Colors and Sizes. Businesses can customize bags in different colors, sizes, and shapes based on their brand image or intended use. For example, a food company may require oil- and moisture-resistant bags, while retailers prefer thicker shopping bags with sturdy handles. Guanzhong offers a range of thicknesses from 20 to 120 microns, tailored to the bag’s intended use, providing flexibility for a variety of applications.

Furthermore, Guanzhong’s customized MOQ is only 1 ton of raw materials, making it particularly attractive for companies first experimenting with eco-friendly packaging. Compared to the high minimum order quantities commonly found in the industry, Guanzhong’s flexible production model allows customers to test market response at a lower cost and gradually expand order sizes.

Throughout the entire production process, Guanzhong adheres to strict sampling and quality inspection standards. Only after the customer confirms the sample will mass production begin. During the production process, each batch of material undergoes tensile testing, puncture resistance, and heat seal strength testing to ensure the reliability of the finished product.

From concept design to proofing to mass production to packaging and shipping, every step is managed by dedicated personnel, eliminating the need for customers to worry about supply coordination.

Guanzhong’s Manufacturing Advantages and Capacity

Guanzhong is more than just a biodegradable garbage bag manufacturers; it is an environmentally friendly packaging company with a comprehensive production system and internationally certified standards. Its 100,000-square-meter modern factory is equipped with advanced film blowing lines, fully automatic printing machines, bag making machines, and cutting equipment, ensuring fully automated production from raw materials to finished products.

The company boasts an annual production capacity of 90,000 tons, enabling it to consistently meet large-volume orders from various regions around the world. This large-scale production not only improves delivery efficiency but also effectively controls production costs, allowing customers to enjoy high-quality products at more competitive prices.

Guanzhong boasts 180 skilled production staff, including experienced equipment adjusters and quality inspectors. Each production line is managed by a dedicated team working in shifts to ensure consistent product quality and delivery schedules.

In terms of quality management, Guanzhong strictly adheres to the ISO9001 quality management system. Its products comply with international biodegradable certification standards such as BPI, EN13432, and OK Compost, ensuring smooth export to European, North American, and Southeast Asian markets.

In addition, Guanzhong has established a comprehensive testing center to monitor key material indicators such as biodegradability, heat seal strength, and tensile properties. All products undergo quality inspections before shipment to ensure that every bag meets customer environmental and usage standards.

Application Scenarios and Market Trends of Degradable Bags

Today, the use of degradable bags is no longer limited to supermarkets. With the implementation of environmental protection policies in various countries and rising consumer awareness, their market scope is continuously expanding.

In the retail industry, degradable shopping bags have become almost standard equipment in large supermarkets. They are not only aesthetically pleasing and strong, but also have no environmental impact after degradation, thus meeting corporate social responsibility (CSR) requirements.

In the catering and food delivery industries, more and more brands are choosing to use degradable takeout bags, takeout bags, and cutlery bags. This is not only a reflection of the environmental trend but also a part of brand image upgrading. Consumers feel a sense of responsibility when using a product, and are more likely to develop a favorable impression of the brand.

In the logistics and express delivery industries, biodegradable mail bags and packaging films have become a new growth area. With the growth of cross-border e-commerce and domestic express delivery, the pollution caused by traditional plastic mail bags has become a concern. The use of biodegradable mail bags can both protect products and reduce plastic waste.

Guanzhong provides customized solutions for clients across various industries. For example, catering clients choose PLA bags with breathable holes to prevent water accumulation during hot food delivery; retail clients use PBAT composite bags for both strength and flexibility; and express delivery clients use thicker double-layer biodegradable mail bags to ensure safe delivery.

Governments around the world are accelerating the adoption of environmentally friendly packaging. For example, the EU will ban single-use plastics starting in 2021, and the United States, Canada, and South Korea have also successively implemented plastic bans. These policies create enormous potential for the biodegradable bag market. Leveraging years of export experience and international certifications, Guanzhong has already established a presence in overseas markets, becoming the preferred supplier for many brands.

How to choose a high-quality biodegradable bag manufacturer?

There are many bags on the market claiming to be “biodegradable,” but not all of them are truly environmentally friendly. When selecting suppliers, companies should consider the following aspects:

First, material traceability and certification. Truly biodegradable bags must be tested by international certification bodies, such as EN13432 or OK Compost. These certifications require that the product completely degrades within a specified period of time and is non-toxic and harmless. Guanzhong provides all biodegradable bags with relevant certification reports, giving customers peace of mind when exporting to demanding markets.

Second, production capacity and delivery guarantees. On-time delivery of large orders is crucial to a stable supply chain. Guanzhong’s 90,000-ton annual production capacity and automated production lines ensure timely production and delivery, regardless of order size.

Third, customization capabilities. For brand clients, packaging is more than just a container; it’s an important vehicle for conveying their brand image. Guanzhong offers one-stop support, from printing design to packaging solutions, making brand packaging more recognizable.

Fourth, after-sales service and partnership experience. Excellent manufacturers provide not only products but also solutions. Guanzhong has many years of experience in international OEM/ODM cooperation and can tailor raw material formulations and bag designs to meet customer market needs, providing clients with truly achievable eco-friendly packaging solutions.

Choosing Guanzhong means choosing a partner with strength, responsibility, and credibility.

| Start Your Customization | WhatsApp: +86 13665956245 | Email: peters@quanzhong-bio.com |

In this era of sustainable development, eco-friendly packaging is no longer just a policy priority; it’s a core competitive advantage for businesses. A truly responsible brand prioritizes not only product quality but also the environmental impact of its products after they leave the consumer.

Guanzhong understands this deeply. With robust manufacturing capabilities, flexible customization services, and a deep understanding of biodegradable materials, Guanzhong is bringing green packaging into more people’s lives.

Starting with a single, biodegradable bag, companies can reduce the burden on the planet and add value to their brands.

If you’re looking for a reliable, professional, and environmentally conscious manufacturing partner, Guanzhong is the ideal choice for a secure partnership.