Table of contents

Overview of China’s Biodegradable Bag Industry: Market Structure and Development Trends

The biodegradable bag industry is growing rapidly under global trends like “plastic restriction,” “carbon neutrality,” and sustainable consumption. MarketsandMarkets predicts the global biodegradable plastics market will exceed USD 20 billion by 2030, with a CAGR of over 9%. China is both a leading consumer and a major manufacturing and export base.

Since 2020, Chinese policies such as the “Plastic Pollution Control Action Plan” and the “Dual Carbon Strategy” require major cities to phase out non-biodegradable plastic bags by 2025, accelerating industry upgrades and creating a complete ecosystem from raw material R&D to manufacturing and export.

The industry chain includes:

- Upstream raw materials: PLA, PBAT, and PHA.

- Midstream manufacturing: Film blowing, injection molding, thermoforming, printing, sealing, and packaging.

- Downstream applications: Supermarket and retail bags, garbage bags, mailing bags, food packaging, and pet waste bags.

China leads globally in PLA modification, smart production, and composite material innovation, with exports primarily to Europe, Australia, South America, and Southeast Asia, accounting for about 45% of global supply.

Top 5 Biodegradable Bag Manufacturers in China

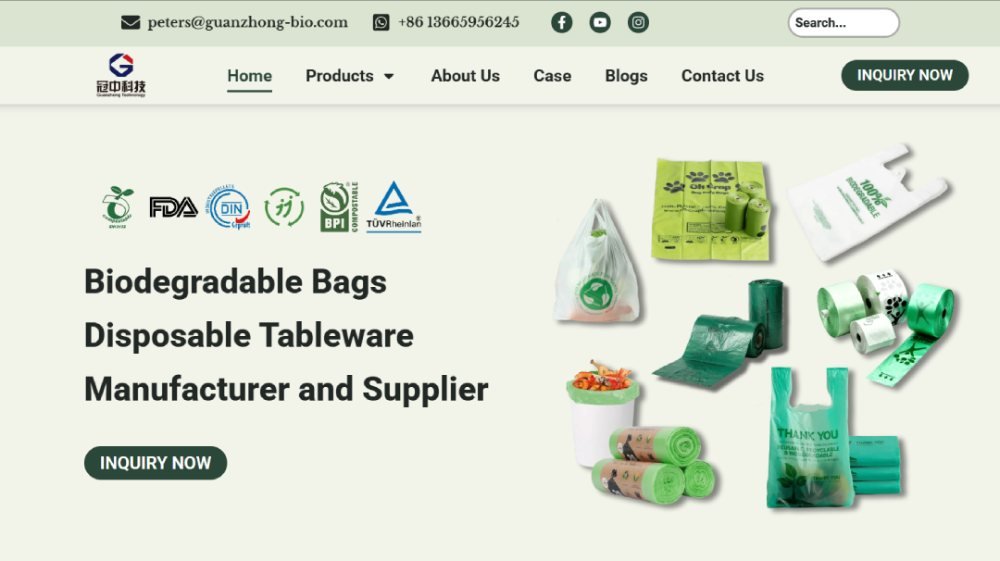

1️⃣ Guanzhong – Expert in Custom Biodegradable Bags

- Company Background: Fujian Guanzhong Technology Co., Ltd., located in Yongchun County, Quanzhou, Fujian Province, covers about 200,000㎡, with 100,000㎡ of production workshops, 180 employees, and an annual output of approximately 90,000 tons.

- Core Technology and Materials: Uses corn starch as raw material, forming a complete degradation ecosystem including grain selection, lactic acid fermentation, PLA synthesis, and bag forming.

- Production Capacity: 50 automated injection molding lines (approx. 2,000 tons/month), 8 automatic thermoforming lines (approx. 800 tons/month), 50 film-blowing lines plus 25 bag-making lines (approx. 1,500 tons/month), 3 biodegradable sheet extrusion lines plus 5 modified masterbatch lines (approx. 2,000 tons/month), 5 straw extrusion lines (approx. 250 tons/month).

- Product Range: Biodegradable plastic bags, garbage bags, pet waste bags, shopping bags, roll bags, etc.

- Customization: Supports logo, color, thickness, size, and packaging customization; minimum order 1 ton of raw material; mold lead time 7 days; production lead time 15 days.

- Certifications: Passed GB/T 20197, GB/T 19277.1, GB/T 4806.7 tests, and holds EN13432, ASTM D6400, DIN, BPI, and FDA food contact certifications.

- International Market and Export: Products are exported to Europe, South America, Australia, and more, offering OEM/ODM services for international brands.

2️⃣ Kingfa Sci & Tech Co., Ltd.

- Company Background: Established in 1993, one of the early developers of PBAT/PLA composite materials in China.

- Technical Strength: Independently develops PBAT and PLA resins with multiple national patents.

- Product Applications: Suitable for supermarket shopping bags, courier bags, takeout packaging, and agricultural films.

- Certifications: OK Compost, EN13432, ISO14001, REACH.

- International Influence: Exports to Europe, Southeast Asia, and South America, supplying international brands.

3️⃣ Xiamen Champion New Materials Co., Ltd.

- Company Background: Focused on R&D and manufacturing of bio-based films and packaging materials.

- Technical Advantages: Multi-layer co-extrusion technology, high-transparency PLA films, excellent mechanical strength, and high-temperature resistance.

- Product Applications: Biodegradable fresh-keeping bags, food packaging films, courier bags.

- Certifications: BPI, OK Compost, EN13432.

- International Clients: Supplies large retail chains in Europe and North America.

4️⃣ Ecosource (Dongguan) Environmental Products Co., Ltd.

- Company Background: PLA/PBAT composite biodegradable bag manufacturer in Dongguan.

- Product Range: Garbage bags, food packaging bags, fresh-keeping bags, kitchen bags.

- Production System: Fully automated film-blowing, printing, and bag-making lines, equipped with intelligent quality inspection.

- Certifications: ISO9001, BPI, OK Compost.

- International Clients: Supplies Walmart, Target, Costco, and other international retailers.

5️⃣ Zhejiang Biogreen Packaging Co., Ltd.

- Company Background: Located in the Yangtze River Delta, specializing in mailing bags, pet waste bags, garbage bags, and shopping bags.

- Production System: Fully automated film-blowing and printing bag-making equipment, strict quality control system.

- Certifications: EN13432, BPI, OK Compost, ISO9001.

- Export & International Influence: Europe, Australia, South America; stable delivery times, suitable for cross-border e-commerce and international brands.

How to Choose the Right Biodegradable Bag Manufacturer

Choosing the right manufacturer is essential for product quality, cost control, and brand image. Key factors include:

1️⃣ Material and formulation performance: Quality manufacturers offer adjustable PLA/PBAT ratios to balance tensile strength and degradation rate.

2️⃣ Certification completeness: EN13432, ASTM D6400, BPI certifications ensure international market access.

3️⃣ Automation and production capacity: Automated production lines ensure consistency and shorten lead times.

4️⃣ Customization and responsiveness: Flexibility for logo printing, color, thickness, and packaging.

5️⃣ Quality management system: Includes raw material testing, tensile tests, and composting experiments.

Recommended third-party verification platforms: SGS, Intertek, Alibaba Verified Supplier, Made-in-China Verified Factory. Always request certification documents and sample reports before purchase.

Procurement Guide and Customization Tips

Standard procurement process:

Requirement analysis → Supplier screening → Sample testing → Contract confirmation → Production monitoring → Acceptance and delivery.

Key customization considerations:

- Bag type and application: Shopping bags, garbage bags, mailing bags, etc., require matching thickness and material ratio.

- Printing and packaging: Specify eco-friendly inks, packaging methods, and carton sizes.

- Cost control: Optimize MOQ and shipping methods (sea/rail/air) to reduce overall cost.

- Contract terms: Clearly define degradation standards, delivery schedule, compensation, and after-sales responsibility.

Applications and Market Potential of Biodegradable Bags

1️⃣ Main Application Scenarios

- Shopping bags: Used in supermarkets, convenience stores, and e-commerce deliveries, customizable for thickness, material, and printing.

- Garbage bags: Household, catering, and public space bags can undergo soil or industrial composting.

- Mailing bags: Used in cross-border e-commerce and logistics, require strength, toughness, and water resistance, suitable for biodegradable garbage bag manufacturers.

- Takeout packaging: Bags and container seals must comply with food safety standards and tensile requirements.

- Pet bags: Pet waste bags for households and public spaces, safe and degradable.

- Agricultural & horticultural use: Biodegradable mulching films and planting bags that reduce soil plastic residues.

2️⃣ Market Potential

- Policy-driven growth: Global plastic restrictions, carbon neutrality, and zero-waste city initiatives create market opportunities.

- Consumer awareness: Over 65% of consumers are willing to pay extra for eco-friendly packaging, increasing procurement of biodegradable bags.

- Export prospects: Strict standards in Europe, Japan, and Australia create opportunities for Chinese manufacturers.

| Start Your Customization | WhatsApp: +86 13665956245 | Email: peters@quanzhong-bio.com |

China’s biodegradable bag industry is increasingly led by technological innovation and sustainable manufacturing. Leading biodegradable bag manufacturers, represented by Guanzhong, combine real production capacity, comprehensive customization, and strict quality standards to achieve global recognition.

As international environmental policies deepen and green consumption spreads, Chinese manufacturing is shaping the new era of global sustainable packaging. Choosing a reliable manufacturer helps companies fulfill environmental responsibilities and enhance long-term brand value.